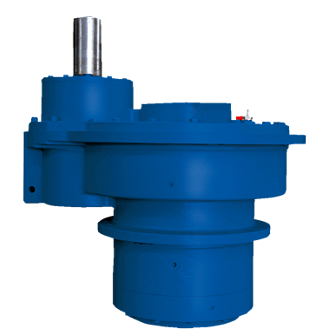

Cover all your special gear needs with Koellmann Gear

Using Koellmann gears, machine and system manufacturers can cover all of their special gear needs. Even the most specialised requirements can be implemented through consulting from the design and production to delivery. This is based on the product expertise that comes with years of experience. Special gears are available with a torque of up to 300,000 Nm and a weight of up to 15 t.