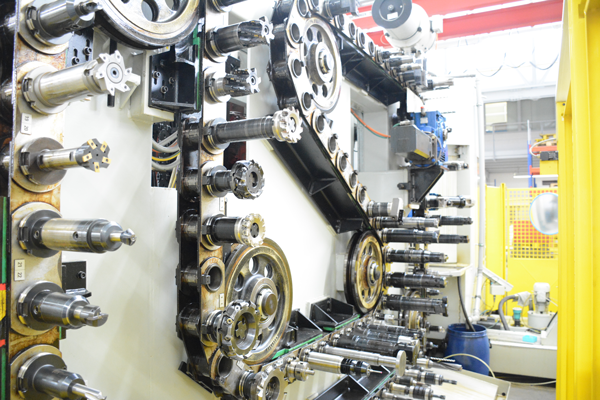

The gear partner for world market leaders

Koellmann Gear

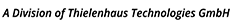

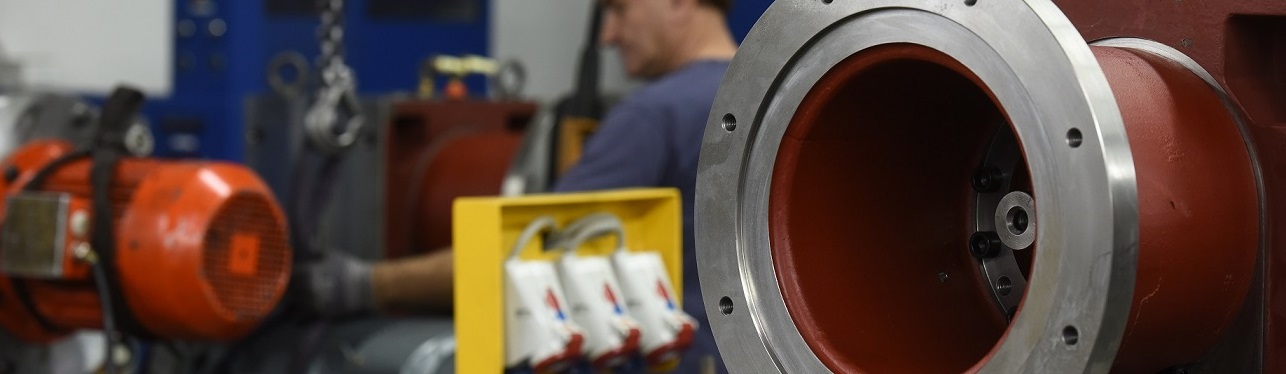

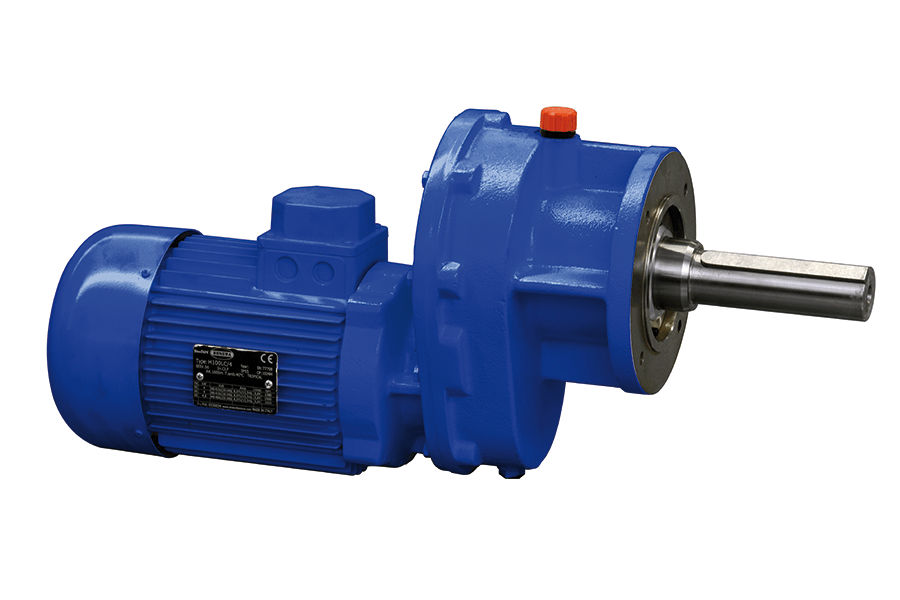

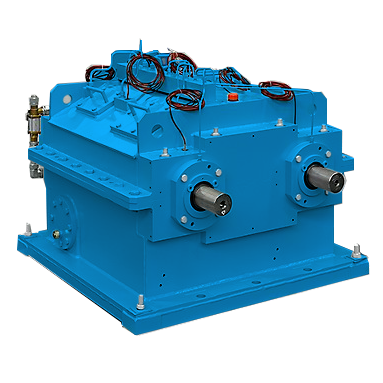

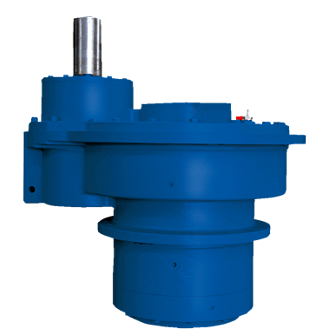

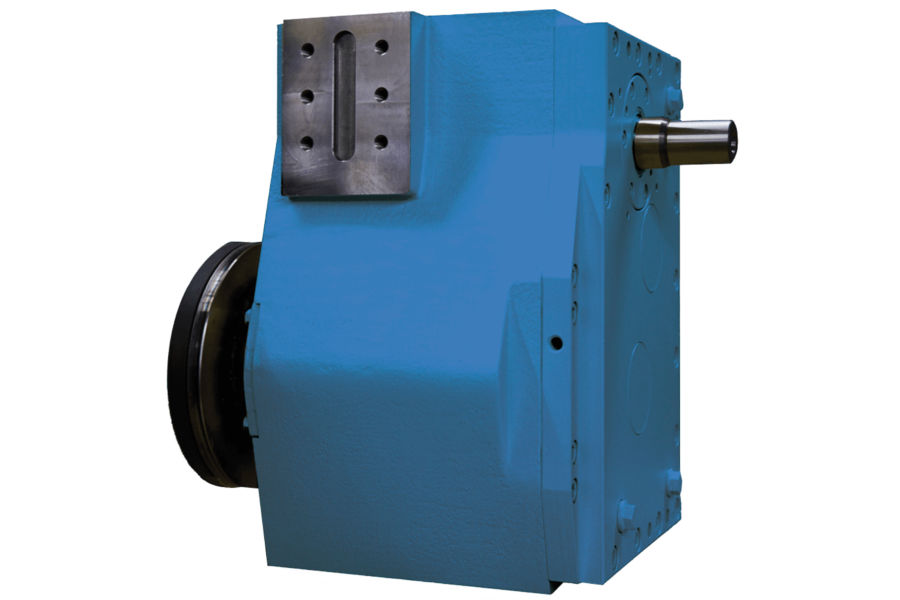

Our Products

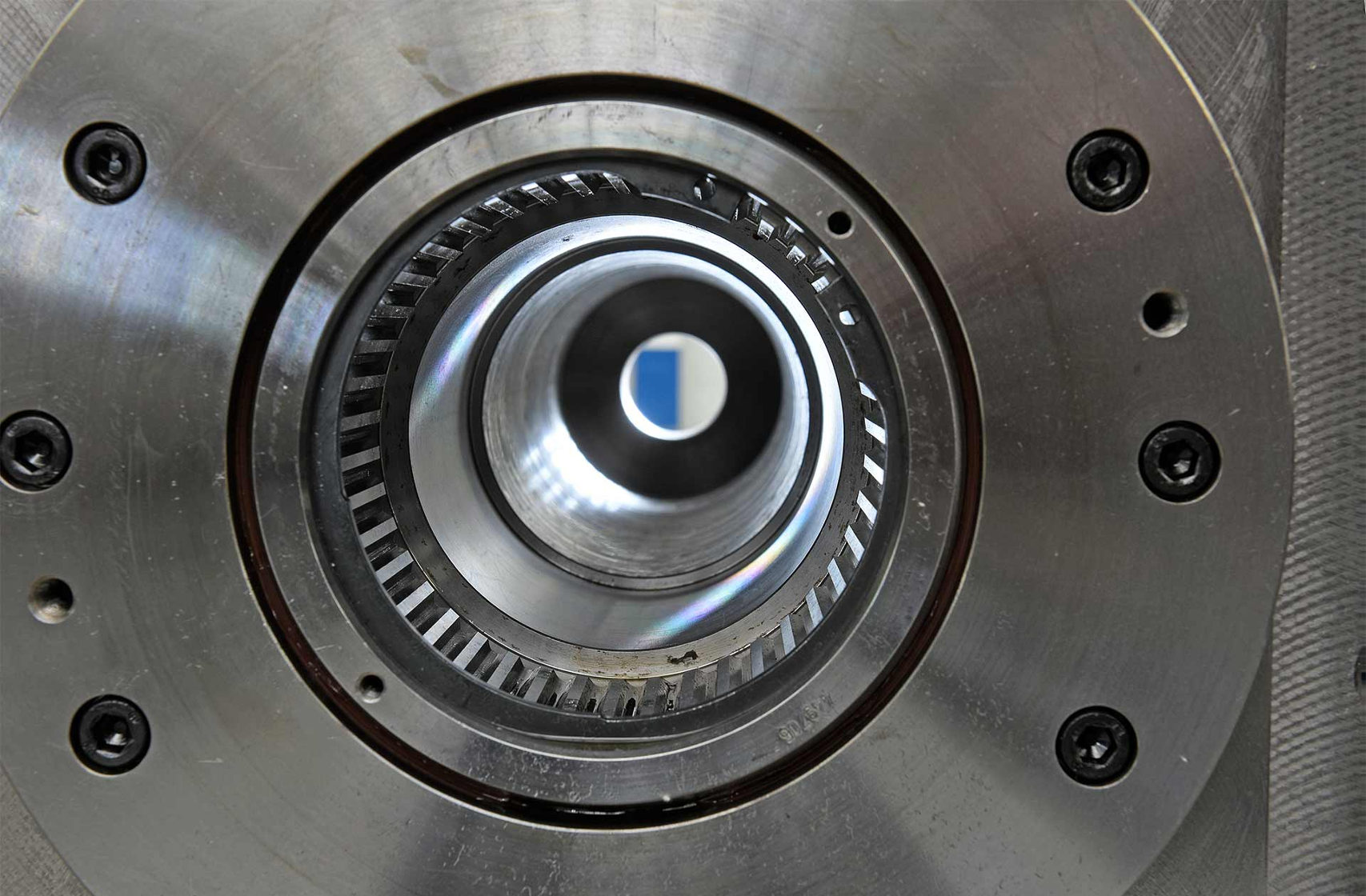

Service in Koellmann Quality

Contact

Our Address

Koellmann Gear Corporation

8 Industrial Park

Waldwick, NJ 07463

U.S.A.

1 201 447 0200

▶ This email address is being protected from spambots. You need JavaScript enabled to view it.